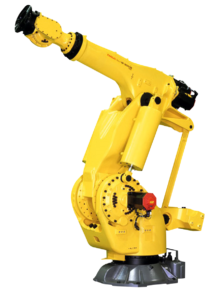

CBE+ is installing the first 6+1 robotic Electroless Nickel Plating (ENP) line in the UK and Europe.

The automated plating line will allow us to undertake a range of innovative projects including the processing of small, precision-engineered components in high volumes and the ability to deliver high-quality parts at a consistently high standard.

We are also automating parts of our jigging process in partnership with the Manufacturing Technology Centre

We have invested £0.75m in a combined heat and power system which will reduce the carbon emissions of the business by 50%.

The system was installed in early 2022.

The power and heat generation system matches CBE+’s production process energy demands. We partnered with Levercor to develop and commission the system.

Levercor and CBE+ spent several months fully understanding the power and heat demand profiles working together to develop a bespoke system, tailored to fit our processes and unique to our facility.

The system works by capturing the heat generated as a by-product of the electrical power generation and uses it to provide heat energy, warming the tanks for surface treatment processes.

A new effluent plant has been installed at CBE+. The plant is used to filter and neutralise all waste chemistry generated on site, allowing environmentally safe disposal and recycling.

This system is an important complementary addition to our Electroless Nickel Plating (ENP) process. Compared to other manufacturing processes at CBE+, ENP is heavily reliant on the use of chemicals.

Our state of the art, new effluent system is in place to purify all solutions produced in the plating process and restore them to environmentally friendly standards, approved by Yorkshire Water.

We provide unmatched production capacity and turnaround times.

We have an extensive range of highly equipped in-house inspection and testing facilities.

We are introducing automated processes to our capabilities creating industry leading efficiencies.

We offer technical consultancy to develop and deliver exact procedures to meet your specific requirements

We have some of the largest plating tanks in Europe.