‘Right first time’ describes our approach to quality and inspection. We capture, measure and monitor data from all areas of our business to continually improve how we operate as a company.

We know that we are ‘only as good as our last part’ and on that basis we employ a full-time inspection department to ensure that all parts reach our customers ‘right first time’.

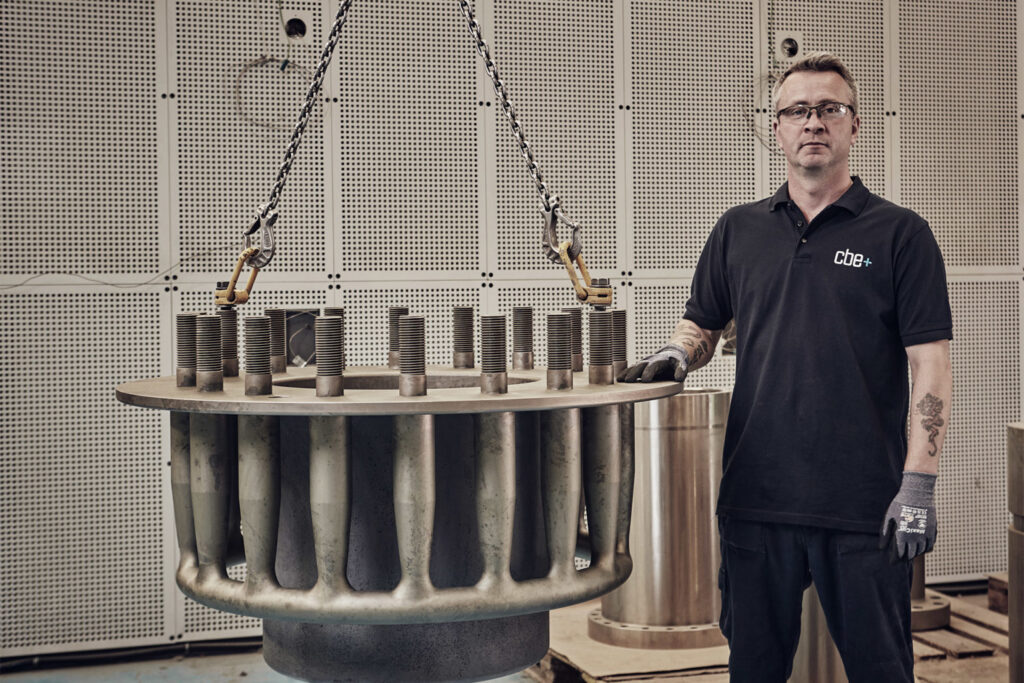

We foster a culture of quality at CBE+, with every operation performed by highly trained engineers and inspectors, ensuring all processes are completed in accordance with customer specifications and standards.

Our company objectives are set and monitored by our Directors and are subject to formal evaluation as part of our regular QMS management reviews. All our employees are committed to implementing the requirements documented in our Quality Manual and are responsible for ensuring these quality standards are applied to all aspects of their work.

CBE+ holds AS9100 and ISO9001

CBE+ENP also holds AS9100 and ISO9001:2015

CBE+ operates an engineering and manufacturing focused ERP system, controlling all aspects of production from quotation, part & process build up through to finite capacity planning and scheduling. The systems affords us complete traceability through its comprehensive works order management facility and shop floor data collection system.

We provide unmatched production capacity and turnaround times.

We have an extensive range of highly equipped in-house inspection and testing facilities.

We are introducing automated processes to our capabilities creating industry leading efficiencies.

We offer technical consultancy to develop and deliver exact procedures to meet your specific requirements

We have some of the largest plating tanks in Europe.

Capabilities Beyond Engineering, Enterprise Drive, Williamthorpe Industrial Park, Holmewood, Chesterfield, S42 5UZ

01246 529014