At CBE+, our highly skilled technical engineers and CNC machinists work with a wide range of materials from food grade plastics to aerospace alloys.

We have 3 and 4 axis machine tools, in various sizes all the way up to our 10-pallet Okuma Flexible Manufacturing System, so we can accommodate small batch production as well as long running production series.

We use the latest tooling and backup from major manufacturers to create cost savings whilst still producing tight tolerance, high quality products.

In 2023 we have invested in our first 5-axis machining centre, the Spinner U630. The new machine expands our precision engineering capability and capacity while boasting numerous benefits for our customers.

BENEFITS

Accreditations

AS9100 (rev. D)

ISO 9001:2015

We use specialist software to control our turning process, ensuring precision and attention to even the smallest detail.

Using the latest tooling and backup from major manufacturers, we can deliver cost savings while still producing tight tolerance, high quality products.

Our approach to investment in new equipment focuses on the quality of the machine tool, we deal extensively with high quality suppliers including Okuma and Mazak to ensure we have the confidence to deliver superior subcontract manufacturing service to our customers.

Accreditations

AS9100 (rev. D)

ISO 9001:2015

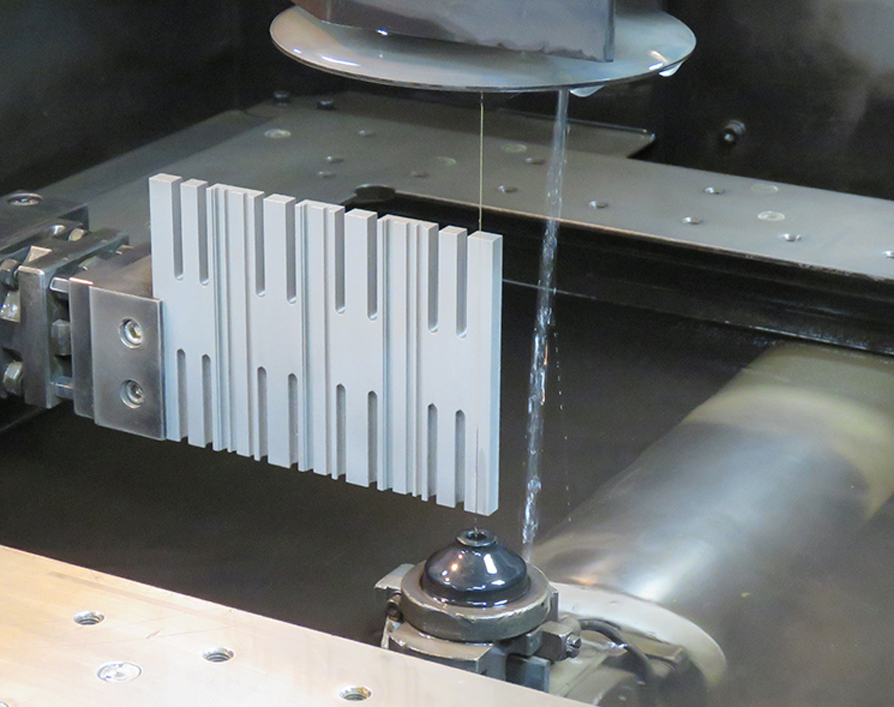

Wire EDM (Electrical Discharge Machining) allows precise machining of the hardest components and complex geometrics where CNC machining is difficult to achieve.

The team has over 30 years of combined experience in manufacturing highly accurate parts including:

Automotive | Motor sport | Toolmaking | Aerospace | Medical implants and instruments | Food processing

Wire EDM Machining, is a CNC-controlled machining process for electrically conductive materials, where a thin single-strand metal wire cuts profiles using electricity, by means of precise metal spark erosion. Electrical pulses are generated between the wire electrode and the workpiece, deionised pure water acts as a semiconductor between the workpiece and the energised wire to ensure controlled conditions for ionization within the spark gap. As a voltage is applied, the fluid ionises, and a controlled spark vaporises a small section of the workpiece.

Originally used in press tool manufacturing, the technology has advanced significantly over the years. Machines have improved cutting speed and accuracy, leading to use in sectors such as aerospace, Formula One, automotive, medical, and electronic industries. Because of its versatility, manufacturers use WEDM operation for an extensive range of applications. It is often an ideal choice to produce small, highly detailed items that would normally be too intricate for other machining processes.

Wire Electrical Discharge Machining can cut anything that is electrically conductive regardless of the hardness, from common materials such as tool steel, aluminium, copper, and graphite to exotic space age alloys including hastaloy, waspaloy, Inconel, titanium, carbide, polycrystalline diamond compacts and conductive ceramics.

The accuracy, surface finish and time required to complete a job is extremely predictable. Additionally, the process is cost-effective for low-quantity projects and can prove beneficial in prototype manufacturing, even if the actual project is carried out by different means.

Benefits include:

The wire (normally brass 0.3mm diameter) does not touch the workpiece, so there is no physical pressure impacted on the workpiece compared to grinding wheels and milling cutters. The amount of clamping pressure required to hold small, thin, and fragile parts is minimal, preventing damage or distortion to the workpiece. Parts that have complex geometry and tolerances do not rely on different skill levels or multiple equipment.’

The Wire EDM capabilities offer more diversity to CBE+’s service offering. Wire EDM enables the Company to produce highly accurate machining of complex parts in a wide range of materials, including hardened steels.

These machines complement our existing range of CNC milling and turning capabilities and allow us to create tapers, small radius, complex contours, and surface finishes within tolerances of just a few μms.

Our WEDM machines are designed to perform:

Our state-of-the-art, precision engineering facility takes our customers’ products from ‘on-paper’ concepts to complex components. With over 30 years’ experience in CNC Machining, our advanced equipment paired with the knowledge of our team allows us to provide innovative solutions for a range of mission-critical applications.

Our products are used in the most demanding industries in the world, including aerospace and defence, energy and renewables as well as in a huge range of industrial applications.

The sheer versatility of our CNC Turning and Milling centres allows us to machine a diverse portfolio of products and geometries. Our highly skilled technical engineers and CNC machinists have experience in processing forgings and castings in a range of materials, including metals such as steel, titanium, aluminium, Nimonics and superalloys.

We also use the latest tooling and backup from major manufacturers to create cost savings whilst still producing tight tolerance, high-quality products.

CBE+ have a variety of Milling and Turning capabilities incorporating multitasking machines and turn cut functions. Mazak & Okuma are our preferred operating systems.

Mazak use their own programming language called Mazatrol which allows fast part programming and quick turn-around times.

Okuma have their own powerful OSP operating system. The Okuma LB3000 can multitask milling and turning operations including y-axis programming.

Our 2+3 axis Multus has twin spindles and a 40-tool carousel making it able to do complete jobs. It can do part transfer onto the opposite spindle and 3+2 programming.

The various vertical machining centres including Doosan and Cincinnati use the popular Fanuc control.

CBE+ has 3 horizontal machining centres with Multiple Pallets plus 100+ tool station cribs, and they are all equipped with turn cut function. This allows for multitasking operations enabling turned features in the same operation as milling, reducing overall processing time.

If the CNC Turning centre has only one turret, all the work can be completed from one side. However, some turning centres have a main spindle and sub-spindle, with multiple axes, for faster operations, in this situation, the main spindle partially machines the component, which is then moved to the sub-spindle to complete the job on the other side of the part. The speed of CNC Turning processes makes it an ideal operation for large production runs with short lead times.

Some CNC Turning centres will also have live tooling. This means that the tool will rotate as the workpiece stays still, the same process as milling. These machines are referred to as mill/turn machines and can be useful when minor milling details are required on turned parts.

CNC Turning often produces parts quicker and more cost-effectively than milling. CNC Milling is limited to the range of motion of the cutting tools. CNC Turning can sometimes be better suited for complex design options and can be beneficial with faster and more cost-effective machining operations.

AS9100 REV D BS EN 9100:2018

ISO 9001:2015

We provide unmatched production capacity and turnaround times.

We have an extensive range of highly equipped in-house inspection and testing facilities.

We are introducing automated processes to our capabilities creating industry leading efficiencies.

We offer technical consultancy to develop and deliver exact procedures to meet your specific requirements

We have some of the largest plating tanks in Europe.

Capabilities Beyond Engineering, Enterprise Drive, Williamthorpe Industrial Park, Holmewood, Chesterfield, S42 5UZ

01246 529014