Providing 30+ years of corrosion protection.

Electroless nickel plating creates a uniform nickel coating providing a wide range of benefits including superior corrosion protection, improved surface hardness, wear resistance, conductivity and shielding.

We provide specialist surface treatments including electroless nickel plating, diffused nickel plating, shot blasting and heat treatment for customers in niche markets including aerospace, defence, oil & gas and automotive.

Accreditations

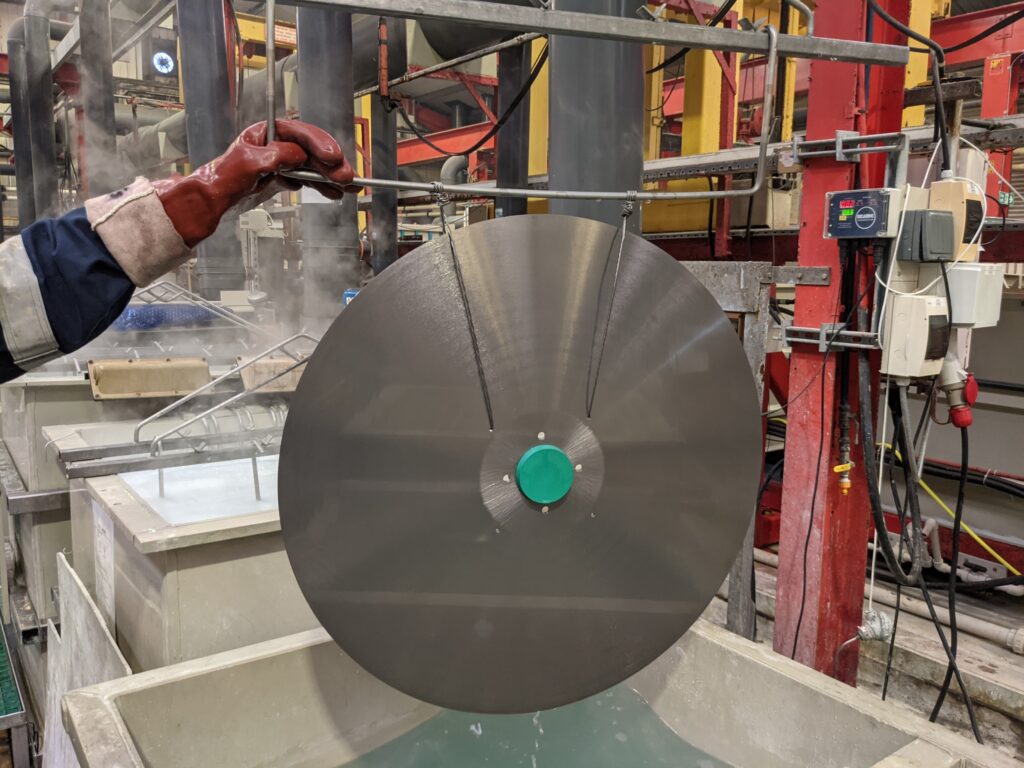

During the Electroless Nickel Plating process, a nickel salt and hypophosphite solution serves as a bath for the base material. Once the component is in the solution, the base material acts as a catalyst to the deposition of the nickel-phosphorous onto the product. This results in increased hardness, wear resistance and lubricity, providing up to 30 years corrosion protection in subsea environments.

Placing the component to be plated, (a suitable catalytic substrate) in the heated plating bath, triggers hypophosphite ions to be oxidised into orthophosphate. A portion of the hydrogen given off by this process is absorbed into the catalytic substrate surface. Ionic nickel at the surface of the catalyst is then reduced by the absorbed active hydrogen to metallic nickel. Simultaneously some of the absorbed hydrogen reduces a small amount of the hypophosphite at the catalytic surface to water, hydroxyl ion and phosphorus resulting in a Nickel Phosphorous coating. The process continues autocatalytically increasing the thickness of the deposition until the component is removed for the plating bath.

Electroless Plating will also leave a nickel coating that is free from flux-density or power supply issues and produces an even deposit regardless of the surface’s geometry or shape, unlike electrolytic.

With Electroless Nickel Plating, a variety of different finishes can be obtained. Nickel is generally known for its adaptable finish, it can be adjusted for a matte or semi-bright finish, making it a versatile option. However, Electroless Nickel Plating will not cover or fill any surface imperfections. For example, if plating a polished component, the finished result will be a polished surface. Additionally, if plating a matte component such as a cast iron, the resulting finish will be a matte finish.

Electroless Nickel Plating is the preferred choice not only for its excellent results, but for its cost-efficient process.

COPPER COLD PLATES / COPPER HEAT SINKS

What? These are used to cool power electronics.

Why? ENP is the only coating which can be applied to the intricate internal cooling systems.

ACTUATOR BODIES

What? These are devices that produce motion (for example an electronic opening door). We currently provide ENP on actuator bodies for aerospace, Oil & Gas and the processing industry (this could potentially be many more).

Why? ENP is used for protecting the actuator from corrosion caused by pneumatic oil.

HYDRAULIC VALVES AND CYLINDERS

What? We plate hydraulic valves and cylinders used in Sub- Sea applications, Oil & Gas, processing, aerospace and automotive.

Why? ENP provides corrosion protection from extreme temperatures and conditions.

ELECTRIC VEHICLE BUSBARS

What? These are electric vehicle battery packs in which aluminium busbars connect to copper terminals.

Why? ENP prevents galvanic corrosion.

BRAKE PISTONS

What? These are used in the automotive industry.

Why? ENP extends the life of the component, protecting from corrosion caused by brake oil.

Downloads

Ni-PTFE plating is a unique plating solution that combines some of the hardness qualities of Electroless Nickel with the lubricity of Polytetrafluoroethylene (PTFE). The Ni-PTFE plating process has been used extensively in the automotive, engineering and mould and die industries.

Electroless Nickel PTFE composite combines the low friction release properties of PTFE with similar functional wear resistance hardness of electroless nickel. It provides a lubricious, hard, uniform coating that is accurately deposited.

In ENP terms when you’re looking for corrosion protection,

Diffused Nickel Plating or “DNP” really is the gold standard.

Diffused Nickel Plating has all the benefits of Electroless Nickel Plating and more. A specific type of Heat Treatment is employed after the initial plating, to improve the corrosion resistance of Electroless Nickel plating, meeting the demands of more extreme environments.

DNP has been, and continues to be favoured by the oil and industry for a number of years. By incorporating the corrosion resistant properties of Electroless Nickel Plating with the added benefits of Heat Treatment to produce Diffused Nickel Plating, it is possible to extend the operational life of subsea components up to 30 years.

High Phosphorous Diffusion Electroless Nickel is an Electroless Nickel deposit which diffuses, after a specific Heat Treatment, into the carbon steel substrate resulting in a very high corrosion and wear resistance in very severe conditions such as offshore or subsea.

After the application of a layer of High Phosphorous ENP typically 80-100 microns, the components are subjected to a very specific and tightly controlled heat treatment in order to achieve a diffusion layer of 3-5 microns.

This offers a very slightly flexible coating with superior corrosion resistant qualities.

Heat Treatment at 610°C: average diffusion layer thickness of 3 to 5 µm.

After Heat Treatment in an atmospheric oven, a typical olive-green colour appears. In an oven with inert gasses or under vacuum, the deposit maintains its metallic aspect.

CBE+ Diffused Nickel Plating process is the highest standard for corrosion resistance via the plating process.

The adhesion of a coating to its substrate is essential to the long-term performance of the coating itself. CBE+ laboratories perform bend tests in accordance with ASTM B571. This includes the part being bent over a mandrel and the deformed area being examined under a low magnification (4X) for peeling or flaking of the coating from the substrate.

We specialise in the process of micro-section testing.

To carry out a micro-section test, a shim of identical material is plated alongside a customer’s component, using the same method. The plated shim is then cut up using a diamond bladed cutting tool to minimise vibration and assure accuracy.

The resulting sample is then set in clear resin, and polished to a fine finish. The surface of the sample is then etched in an appropriate chemical solution to allow the nickel or diffusion layer to be examined under the microscope.

A UKAS-calibrated slide is then used to accurately calibrate software used to measure these layers, determining the thickness of the cross-section under an optical microscope allowing CBE+ to certify the specification of customers is met and met.

The specification for micro-section testing is BS EN ISO1463 & ASTM B487.

We measure the hardness of metal by using the Vickers hardness test, which provides accurate and reliable results.

A square base, pyramid-shaped diamond is used for testing, and loads are typically very light. Microhardness methods are suitable for testing metals, ceramics, composites, and almost any other type of material. Hardness is defined as the resistance to indentation and determined by measuring the permanent depth of the indentation. As a rule, the smaller the indentation left in the metal, the harder the metal.

To provide accurate results, we ensure that the surface of the specimen is smooth in order to permit a regular indentation shape and good measurement, and the test sample is always held perpendicular to the indenter.

The samples prepared at CBE+ Laboratories are mounted into a plastic medium which enables us to facilitate effective preparation and accurate testing. We also ensure that the indentations made are as large as possible to maximise the resolution of the measurement.

The specification for hardness testing is ASTM E384.

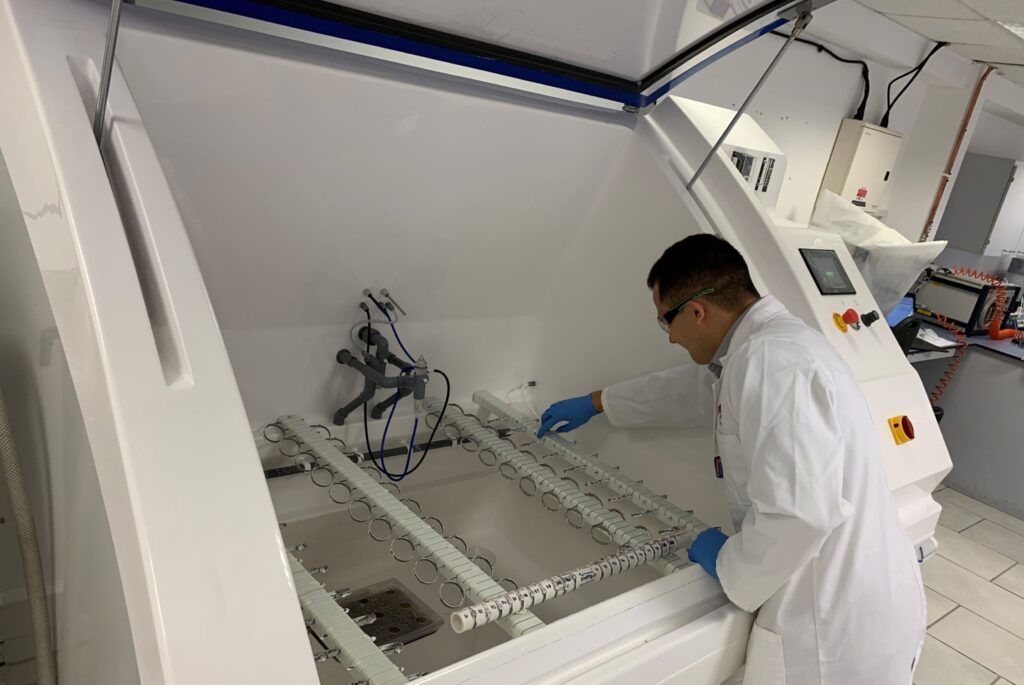

The salt spray test is widely used in the industrial sector. Salt spray testing (salt fog testing) effectively assesses the reliability of a product by simulating extreme environments, therefore confirming that an industrial coating will survive in its working environment. The salt spray test is used to check the corrosion resistance of coated samples, substrates, and components which may be prone to suffering from degradation because of salt corrosion.

The test is conducted in a closed salt spray chamber where the sample is subjected to extended exposure to a saline, or salted, spray. The length of exposure time is determined by the material, the coating, and the standard specified.

The salt spray test can be adapted to different levels of corrosion to simulate different environments. As a rule, the more resistant the coating is, the longer the period in testing without showing signs of corrosion. Our expert team are then able to evaluate the part for evidence of corrosion, enabling us to determine the resistance of the sample, ensuring its longevity and reliability.

The specification for salt spray testing is ASTM B117.

We provide specialist Kesternich testing (sulphur dioxide testing) services for a range of metals and metal plated components. Resistance to corrosion is measured in Kesternich cycling.

Acid rain and acidic industrial pollutants are corrosive and can degrade coatings and plated surfaces. Kesternich testing simulates these environments to evaluate the corrosion resistance of the coating substrate or part itself.

Parts or panels are placed inside a specially designed chamber and are exposed to SO2. The chamber in use at CBE+ Laboratories meets the highest safety standards and allows us to create the perfect conditions to carry out accurate and controlled Kesternich testing. The dosing of the SO2 gas is controlled during the test to accurately simulate exposure to chemicals that may be met in natural environments. An evaluation is then carried out to determine the level of corrosion resistance.

Our Kesternich testing services are available to customers worldwide.

We provide unmatched production capacity and turnaround times.

We have an extensive range of highly equipped in-house inspection and testing facilities.

We are introducing automated processes to our capabilities creating industry leading efficiencies.

We offer technical consultancy to develop and deliver exact procedures to meet your specific requirements

We have some of the largest plating tanks in Europe.