What’s the difference between Electroless Nickel Plating and Diffused Nickel plating? Electroless Nickel Plating Technical Manager, Steve Whitehead, takes a look at the main differences between the two coatings and gives advice when each should be used.

“Firstly, it is important to understand the differences between Electroless Nickel Plating and Diffused Nickel Plating and what the properties of each are.

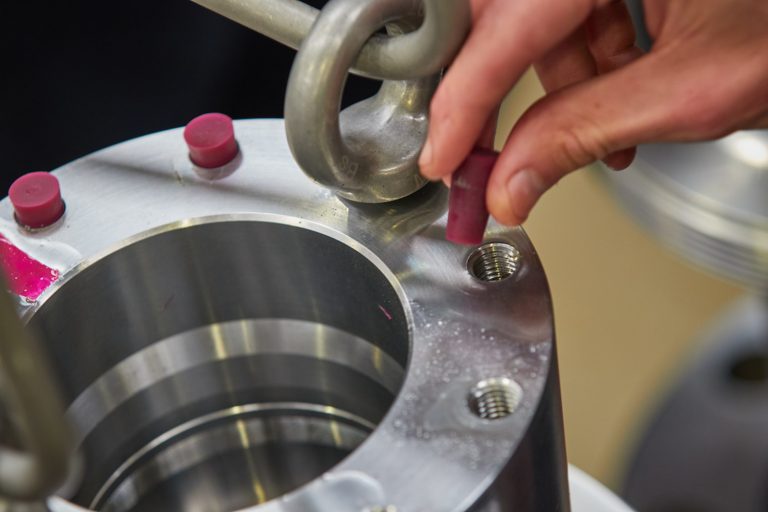

Electroless Nickel Plating is the deposit of a nickel-alloy coating by chemical reduction – without the use of an electric current. The chemical solution usually involves a Nickel-Phosphorus deposit containing between 7% to 14% phosphorus and a chemical reducing agent, such as sodium hypophosphite. This creates a Nickel-Phosphorus alloy coating – it is phosphorus which gives the component the corrosion resistance.

When a component is plated with Electroless Nickel, it has a durable, smooth, corrosion-resistant coating even when covering recesses, holes or parts of a complex geometry. This coating is highly sought-after in many industries, such as aerospace and automotive.”

In the process of Diffused Nickel Plating, the component is first exposed to the chemical treatment which includes Electroless Nickel of a high phosphorus content. After this the component is given a specific heat treatment – this process typically uses Heat Treatment at 610°C. As a result, a diffusion layer is created between the Electroless Nickel deposit and the steel substrate which is typically between 3 to 5 µm.

The benefit of having heat treatment after the Electroless Nickel Plating process is that it is now possible to extend the operational life of subsea components by up to 30 years.

Diffused Nickel Plating is also popular within the marine industries due to its corrosion resistance compared with the high cost of manufacturing in stainless steel.

Our Electroless Nickel Plating and Diffused Nickel Plating experts can advise on which process is most suitable for your application. Call our team now on 01246 529014.

We provide unmatched production capacity and turnaround times.

We have an extensive range of highly equipped in-house inspection and testing facilities.

We are introducing automated processes to our capabilities creating industry leading efficiencies.

We offer technical consultancy to develop and deliver exact procedures to meet your specific requirements

We have some of the largest plating tanks in Europe.