The programme, which showcases the very best of British manufacturing, featured the complete process of razor blade manufacture, from metal injection moulding to handle cutting and detailing, bead blasting and electropolishing. CBE+ Precision proudly machines the company’s renowned 316 razor handle.

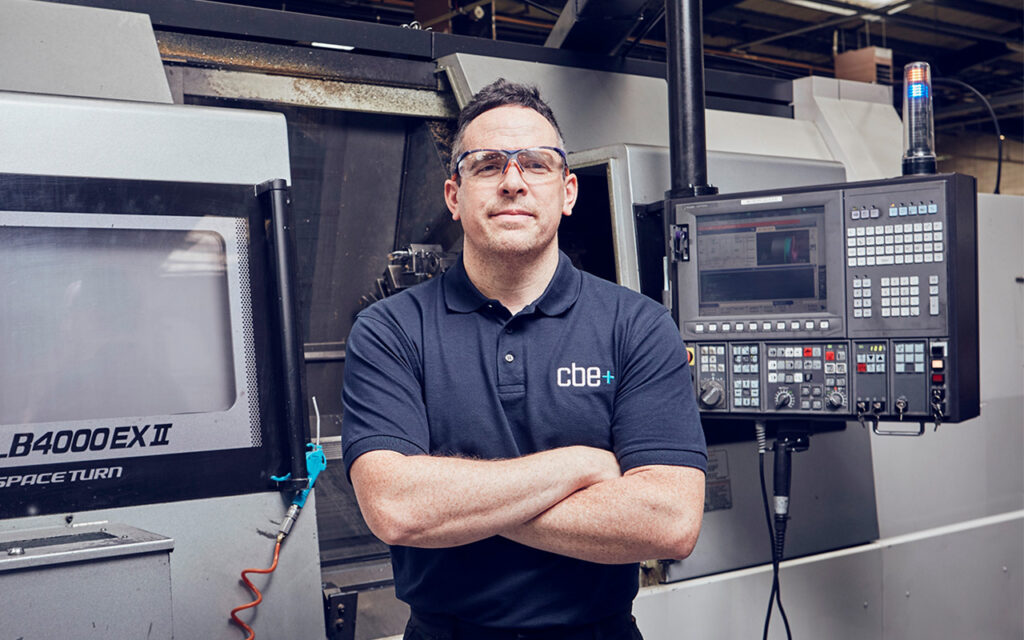

Chris Brown, CEO at CBE+ Precision, explains: “It was great that the company was involved with the Made in Britain TV programme and that we were part of this very specialist manufacturing process for Edwin Jagger. We provide precision engineering services to a wide range of different sectors and it is fascinating to see the numerous different applications where our components end up!”

CBE+ and its businesses are based on Williamthorpe Industrial Estate in Chesterfield, in an 80,000 ft 2 facility that was originally the base for BG Engineering, a leading subcontractor of precision machined components, now known as CBE+ Precision.

Pentag Gears, now CBE+ Gears, a designer and manufacturer of high-quality gearing, and CBE+ Artificial Lifting relocated to the facility in late 2018, which was followed by Spire Laboratories in partnership with CBE+ which specialises in testing, validation and certification for the plating industry in May 2019. NiTEC Ltd, working in partnership with CBE+, one of the UK’s leading electroless nickel plating specialists will shortly be building its new aerospace line here.

We provide unmatched production capacity and turnaround times.

We have an extensive range of highly equipped in-house inspection and testing facilities.

We are introducing automated processes to our capabilities creating industry leading efficiencies.

We offer technical consultancy to develop and deliver exact procedures to meet your specific requirements

We have some of the largest plating tanks in Europe.