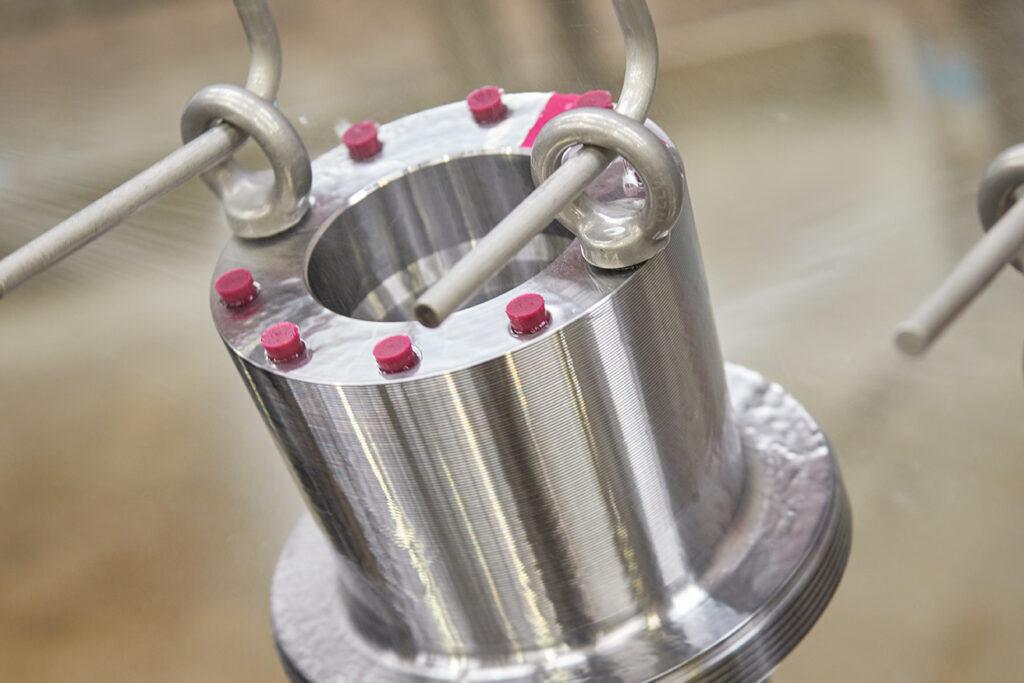

CBE+ invests £2m in Europe’s first robotic automated Electroless Nickel Plating line

CBE+ invests £2m in Europe’s first robotic automated Electroless Nickel Plating line Engineering supply chain provider CBE+ is installing the first 6+1 robotic Electroless Nickel Plating (ENP) line in the UK and Europe at its 70,000sq ft state-of-the-art manufacturing facility. Representing a £2 million investment, the automated plating line will allow the company to undertake […]

Electroless Nickel Plating: Solutions for the most challenging environments

ELECTROLESS NICKEL PLATING: SOLUTIONS FOR THE MOST CHALLENGING ENVIRONMENTS Electroless Nickel Plating Technical Manager Steve Whitehead, looks at some of the industries where Electroless Nickel Plating is helping to create durable, high-performance coatings. When and where to use Electroless Nickel Plating are questions we are often asked by customers. Electroless Nickel Plating is most widely […]

The Definitive guide to Electroless Nickel Plating

ELECTROLESS NICKEL PLATING, WHAT IT IS AND HOW IT CAN BENEFIT YOUR COMPONENTS Electroless Nickel Plating Technical Manager, Steve Whitehead, gives you the low down on everything you need to know about Electroless Nickel Plating. Electroless Nickel Plating (or ENP as it is known) is, in a nutshell, an excellent way of enhancing the […]